Production line Vision Inspection & Defect Rejection System

Plant Control Scheme IIOT Ready

IIoT Cloud Gateways

Some of our Clients

FGR - Committed to Excellence

FGR Automation believes in working with our clients to fully understand their needs and unique problems. It is through this collaboration that we have become a leader, in the development of Advanced Automation and Control Systems. For over 40 years, our custom data driven systems have been implemented on a broad spectrum of projects, in the USA and across the globe. As hardware and software has advanced, we have capitalized on this, to improve performance and features. FGR PLC-PC integrated, data driven systems, offer distinct advantages that contribute directly to Productivity, Profitability, Quality and Safety. Our philosophy is to use readily available hardware and structure software in a modular format, as necessary to facilitate database transactions, as well as additions, changes and modifications. We can help you develop a specification and scope of work for your automation project. FGR has implemented automation projects worldwide, from our facilities in Chicago, Miami and Los Angeles.

Our Products - Industry 4.0 (IIoT) We Know Your Machines & Processes!

FGR HAS EXTESIVE EXPERIENCE of manufacturing operations and understand the pain points and how to limit down-time and improve machine availability and quality. We have learned that the type of sensors and the data represented, is crucial to the prediction of tool wear and machine failures.

MOST RELEVANT: Our solution incorporates dual X-Y axis RMS velocity and RMS HS Acceleration monitoring, Temperature monitoring and the monitoring of Cutting and Coolant Fluids for consistency and quality. Many other points are selectable depending on the machines in play. We are always available to consult on special use cases.

FGR, MANUFACTURES AND SUPPLIES data driven packaged systems that can be easily configured by the user. These units are pre-wired for One (1) to five (5) machines. In a typical use case, a machine group, of up to Twenty (20) Vibration sensors, twenty (20) Temperature Sensors, forty (40) Digital In and Forty (40) Digital Out, and Forty (40) Analog channels is deployable. Connection to most sensors is via an installed radio system that has been tried and tested in multiple factory settings. This enables a quick sensor installation with NO wiring needed. Installation by plant maintenance is normal and can be accomplished in most cases in One (1) day or less per machine. Configuration is a simple menu selection process, using drop-down box selections for; Machine location, input device type, device range, scale, etc…

DISPLAY DATA is available as a web browser so the system can stand alone. For total factory monitoring where hundreds of machines are deployed FGR offers an edge-based solution or alternatively it is compatible with most SCADA systems, Enterprise systems and cloud services.

Additionally, integration from this platform to ‘Big Data’ systems like Azure, AWS and others which, provide the core for deep learning and AI, are seamless.

LEGACY PLC or PC controllers, FGR manufactures an affordable hardware solution that will allow tag data from a PLC/PC to be polled without any need to access the core PLC program and incur associated risks. The system is scalable from 1 sensor of any type to thousands of mixed data points.

SOLAR POWERED units are available for remote locations, where there is no utility power service or connection is not convenient due to location and cost. Resetting of a remote processor can be implemented from any authorized mobile device .

Our - Automation System Solutions

Our engineering team has extensive automation experience across a wide variety of industries. We have the expertise to produce outstanding results with services ranging from software design and development for existing hardware, through the implementation of complete turnkey systems, customized to meet individual client needs.

Specialty Applications

IIoT - Monitor and Control Virtually Any System, Machine, Sensor or Instrument from Anywhere

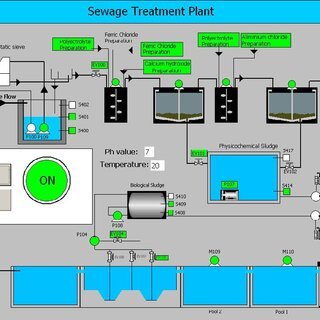

Water and Waste Water Treatment - Total plant control and new technology upgrades including iIOT additions.

Systems for Manufacturing and Automated Distribution - Production line monitoring & part tracking, Prescription drug filling and packaging, Bottling, etc..

Elevator Controls - PLC based none proprietary systems for special applications, eg. NASA Mobile Launcher ML1, NASA Vertical Assembly Building (VAB) Elevators (4) and Porsche Design Tower, High-rise Automobile Elevators (3) with ‘in car passengers’.

Bulk Material Handling and Blending - Conveyors, Trippers, Gates, Feeders, Loaders and Unloaders.

Coal Preparation Plants - Over Fifty Dense Media and Jig Plants Implemented World Wide.

Automated Truck Loading - Systems vary in complexity from simple drive through loading to

integrated truck identification systems with automated billing.Unit Train Loading (Batch Weighing) - RFID Tag Reader for Individual Car Tare and Net Weights, Electronic Billing.

Machine Vision Solutions for Industrial Applications

Packaging Solutions

Vision Systems - Machine Pick and Place Robot Integration, Quality management and Conveyor Belt Fault Detection.

Railway Marshaling Yards - Automated Switches for Hump and Loco Assist.

Furnace Controls - Blast and Walking Beam.

Continuous Casting Machines - Billet, Bar and Slab.

Glass - Primary Float Glass and Fabrication lines, Automobile glass product lines.

Pulp and Paper - Prep Plant and Total Mill Control.